10 QUESTIONS AND ANSWERS ABOUT TRAILER COUPLINGS FROM VBG

Now we’re in the depths of summer, you may be settled in your sun lounger wondering why all trailer couplings from VBG are red? Maybe you’ve been pondering what VBG means? Or why VBG coupling bolts come in 57mm as standard? You need wonder no more! We have the answers to your queries right here!

WHAT DOES VBG STAND FOR?

VBG is an abbreviation for Vänersborg and it was something that founder Herman Krefting noted when he decided on the name Vänersborgskopplingen, which has been developed over the years and come to be known as VBG. Since its origins more than 70 years ago, the business has continued to grow in the town of Vänersborg.

WHY ARE VBG COUPLINGS RED?

Our couplings haven’t always been red in colour. In the 1970s, VBG couplings came in a variety of colours. These colours distinguished between the different models in the range. The red edition is the one to have survived and is now seen on all couplings from VBG.

WHY IS A COUPLING BOLT 57 MM AS STANDARD?

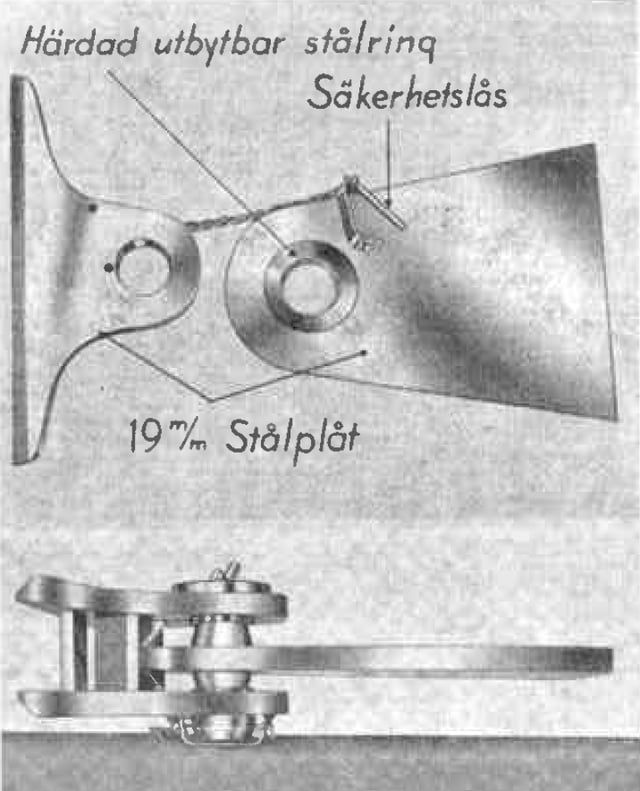

"The most important part of a coupling in terms of traffic safety is the bolt" said VBG’s founder Herman Krefting. When Herman began to think about how he could increase road safety, it was the bolt he identified as the most crucial part of the coupling. To create a reliable and durable coupling, he increased the dimension from the previous standard to 57mm ∅. VBG’s 57 mm bolt is treated using the hard material manganite and has become the present-day Swedish standard.

WHAT DID THE FIRST VBG TRAILER COUPLING LOOK LIKE?

The first coupling, the TYPE 101, had a 57mm bolt and was launched onto the market in 1951.

HOW DO VBG TRAILER COUPLINGS MAKE LIFE EASIER FOR DRIVERS?

Innovation is one of VBG’s watchwords. Here are just a few examples of how at VBG we have worked together with drivers to make their working day safer and easier.

- VBG’s first power actuator, launched in 1984, made it far simpler for the driver to manually open and close the coupling.

- 1994 saw the launch of a green/red light indicator in the cab showing whether the coupling was open/closed in the case of remotely controlled couplings.

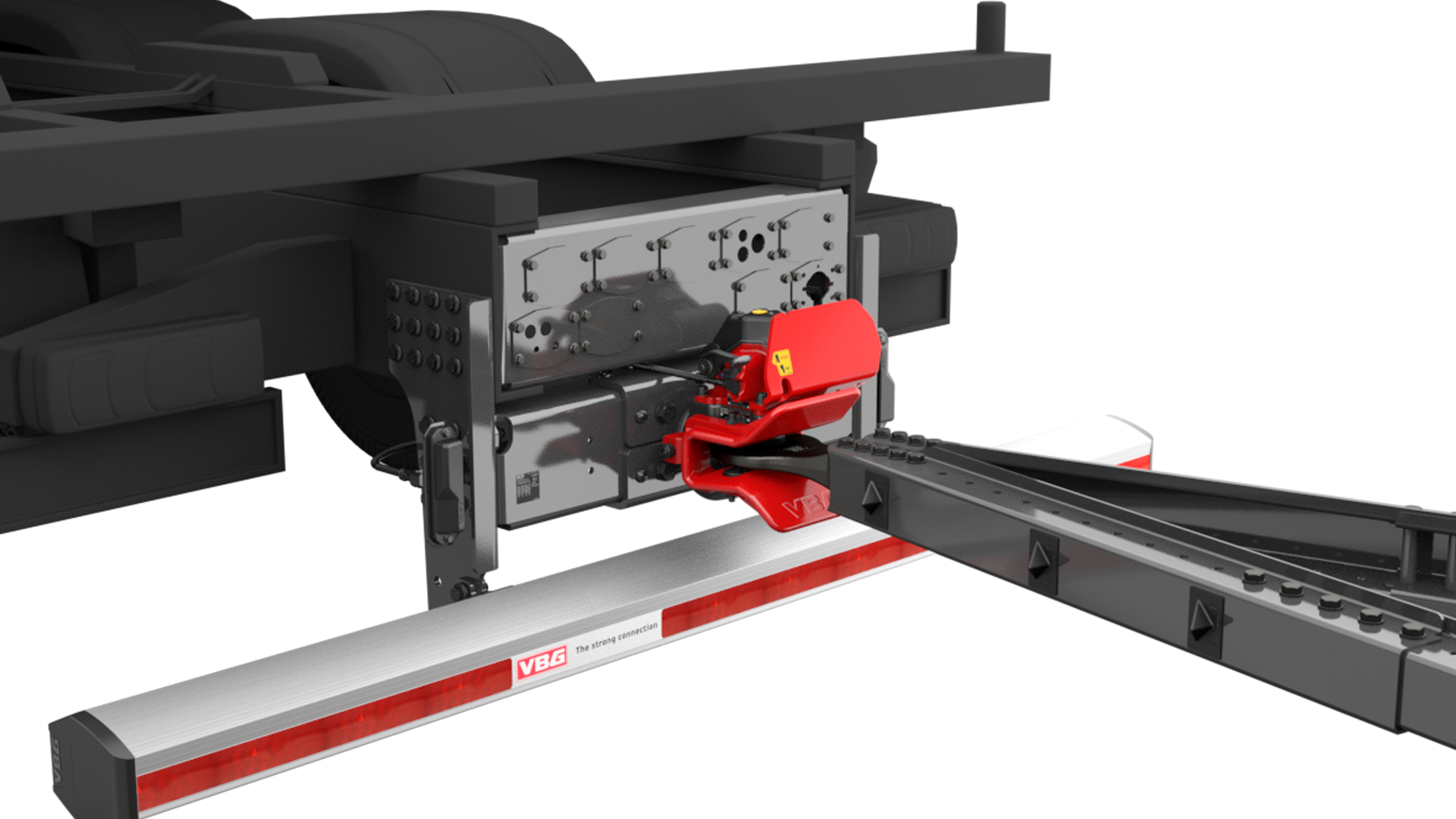

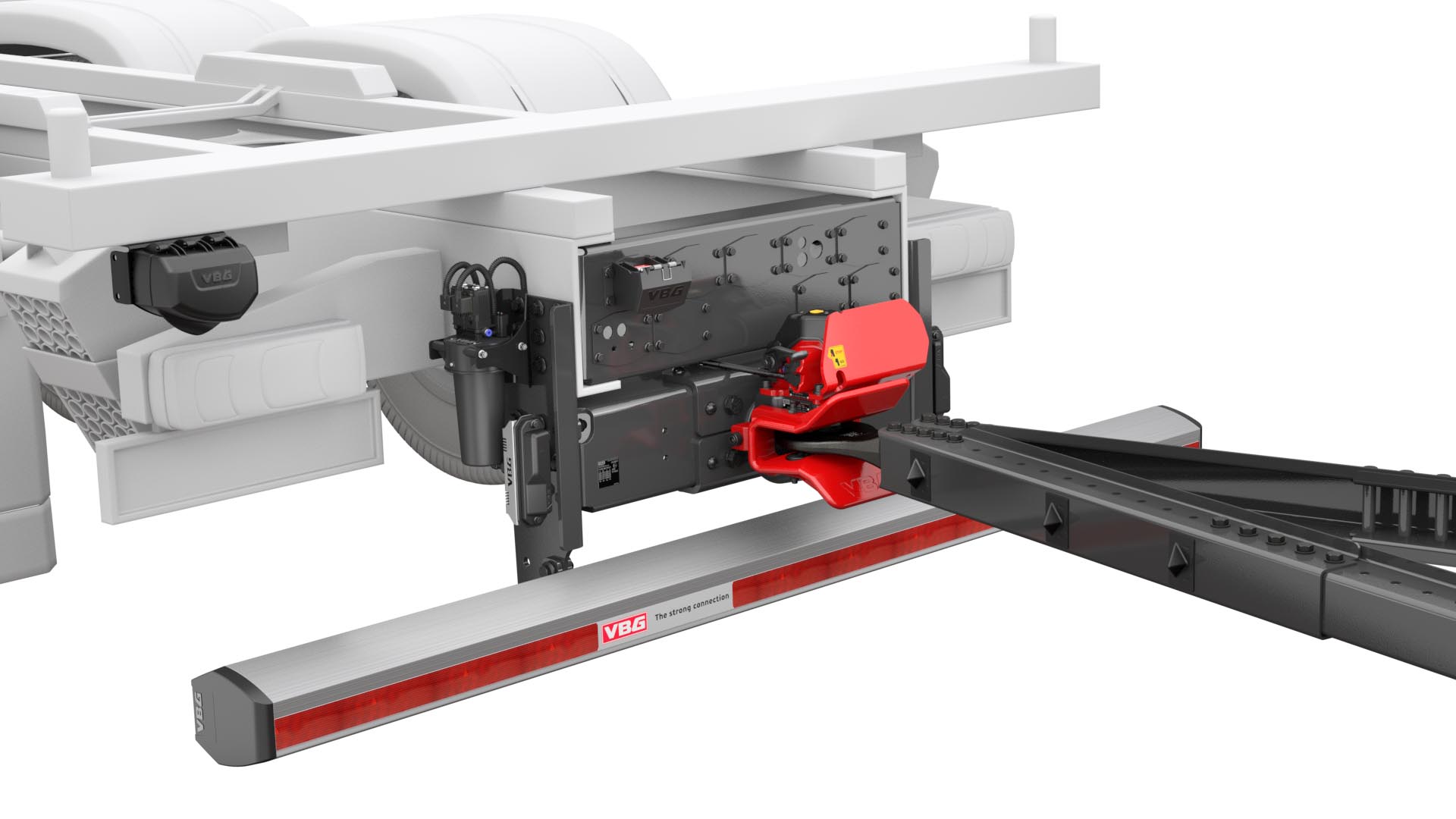

- VBG MFC Multi Functional Coupling, offering fully automated coupling and disconnection, arrived on the market in 2008. The coupling ensures maximum safety and comfort for the driver who no longer has to exit the cab when coupling and disconnecting, which not only safeguards their physical health but also saves time.

- VBG MechMatic is an automatic lubrication system that ensures a longer service-life and reduces coupling maintenance needs. This development sought to ensure that drivers no longer have to remember to set aside time to lubricate manually. Born in 2012, the VBG MechMatic is intended to maintain maximum levels of safety and service-life for couplings.

WHY DO ALL VBG COUPLINGS FEATURING A ROTATING BOLT?

The rotating bolt has been a VBG standard since 1998 and is advantageous both in terms of extended the coupling’s service-life and increasing product safety. The rotation helps to make wear and tear across the whole bolt more symmetrical.

HOW MANY LOCKS SHOULD A TRAILER COUPLING FEATURE?

Since 1994, the EU Directive has required trailer couplings for heavy trailers to feature two mechanical locks while also allowing for the coupling to be opened manually, even when a power actuator is present. As a result, VBG couplings always feature a manual handle regardless of the mode of operation selected.

WHAT IS IT THAT MAKES DRIVING A RIG WITH A VBG COUPLING SO COMFORTABLE?

VBG’s couplings feature two different attachment systems for drawbeams, and these are used for different types of rig and transport.

Trailers fitted with an articulated drawbar that is not exposed to any vertical forces can fit the most comfortable coupling offered by VBG. This is equipped with substantial rubber elements that ensure a smooth passage between the vehicle and trailer.

If you need to tow all types of trailer, then VBG’s Universal attachment system is the perfect solution. This system is designed with smaller rubber elements since it must distribute both vertical and horizontal forces imposed on it by the trailer.

LACE THE ENTIRE MECHANISM IF THE COUPLING BOLT IS WORN OUT?

The mechanism consists of many components, but it is only on the coupling bolt that the wear limit can be determined. Since all components undergo wear, the whole mechanism needs to be replaced for the sake of safety and to ensure functionality.

CAN I GET HOLD OF SPARE PARTS FOR MY COUPLING?

VBG endeavours to take long-term responsibility for our products and customers. This is why a wide range of spare parts and substitute products are available for both our current and discontinued products.

Recommended reading

How Do You Build the Optimal VBG System?

How can new technology streamline and improve the workday for hauliers?