How Do I Build a VBG System?

In 2023, 6,620 heavy trucks were registered in Sweden, most of which are driven with trailers. This places high demands on our products, which act as the link between the truck and the trailer. The coupling equipment comprises many components, which we will go through step by step to help you build the optimal combination of VBG system components for your vehicle.

How do I choose the right products for a VBG system?

Step 1: What are the performance values of the truck combination?

Start by calculating the truck combination’s weight, length, and axle load, and take into account the type of goods it will transport. These values are then entered into the VBG Performance Value Calculator (PVC) to find out the requirements for the specified coupling equipment.

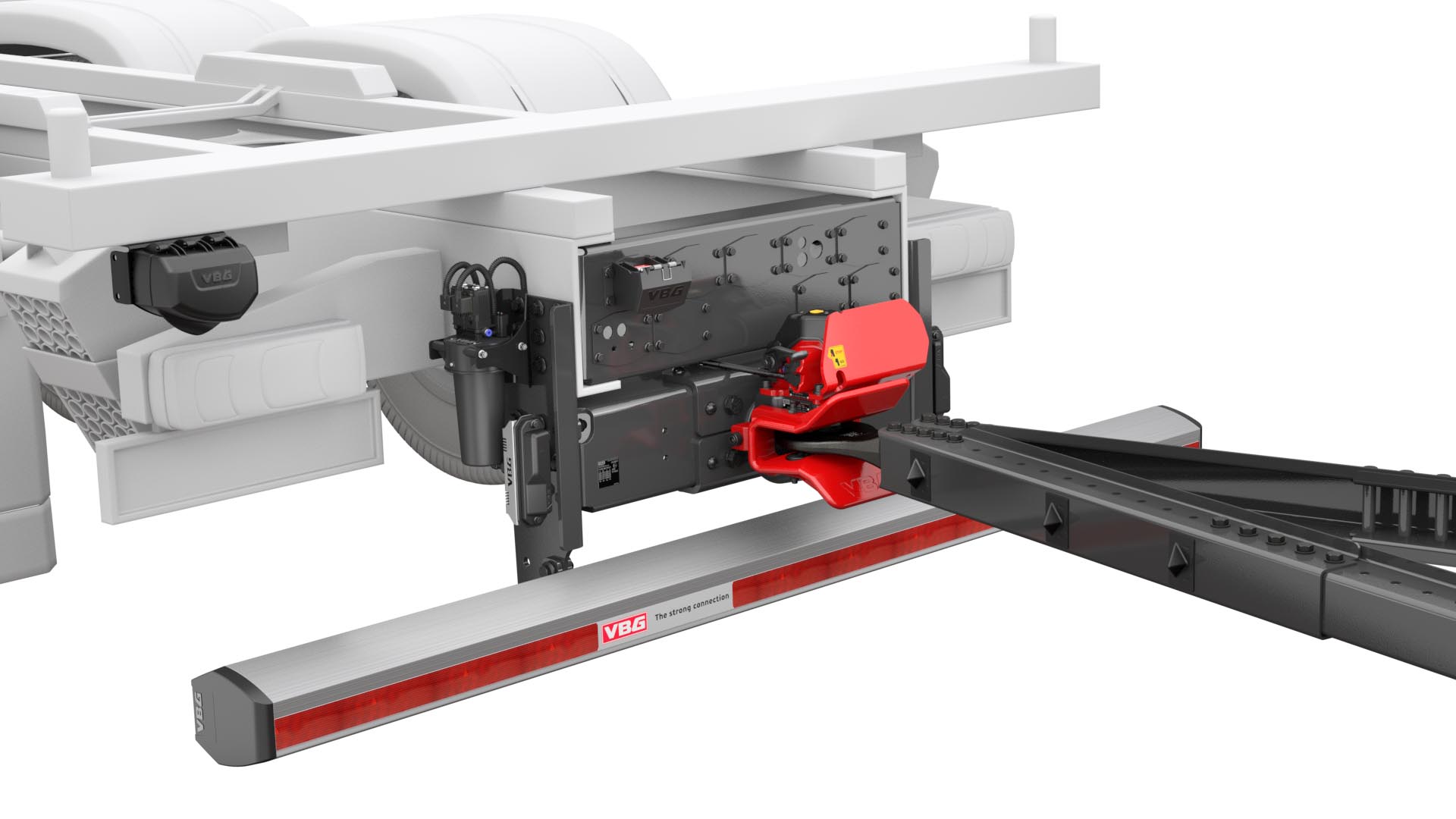

Step 2: Drawbeam system

Now that we know the performance values of the truck combination, it is time to choose the appropriate drawbeam system, which is the link between the coupling and the truck chassis.

There are several options to choose from depending on how you want the coupling to be fitted. Underslung installation is the most common, i.e. the drawbeam is suspended under the chassis using an endplate kit.

Once you have chosen the drawbeam and the type of installation, you need to know which vehicle manufacturer the drawbeam system must fit. You will then need endplate kits; the different endplates are used to achieve the appropriate height for installing the coupling. The endplate kits therefore differ in G size.

What is G mmeasurement?

G-measurement is the measurement between the bottom row of holes on the chassis to the height where the coupling bolt is to be placed.

Here above is our most common endplate, EDH-3. It has a G measurement of 167 mm, which means that it is close under the chassis when fitted.

Which screws are needed to install the drawbeam system?

Each endplate kit comes with assembly instructions that contain information about the type and quantity of screws needed.

Step 3: Which trailer coupling should I choose?

Do you want a manually operated or air-assisted coupling? What coupling mouth length do you need? On our website you will find all our coupling models as well as information about which uses are best suited for each model.

If you choose an air-assisted coupling, you also need to choose a valve box and an indicator kit. The valve box controls the air that opens and closes the coupling. The indicator kit is necessary as it contains the cable that sends the signal to the cab to inform the driver when the coupling is open and closed. The coupling position is indicated by a red or green light on a button attached to the panel. Some vehicle manufacturers have enabled the indicator to appear on the dashboard.

Step 4: Which underrun protection fits your truck combination?

The regulations for underrun protection, UNECE R58 Revision 3, were updated in 2019 and place higher demands than before on manufacturing and materials. The requirements stipulate that underrun protection must be able to withstand higher impact forces. The regulations are being introduced at different times in different countries. Some countries are still awaiting full introduction, with Sweden being an example where Revision 2 is still valid. However, VBG recommends always following the latest requirements to contribute to increased road safety.

To install underrun protection, the G-measurement needs to be measured to find the correct position for the underrun protection. This G-measurement is measured from the bottom row where the drawbeam is mounted to the centre where the underrun protection will be placed.

The underrun protection must be fitted using the mandatory installation kit for secure attachment between the endplate and underrun protection.

Step 5: Smart accessories for coupling equipment maintenance

- VBG MechMatic blows clean and lubricates inside the coupling mechanism completely automatically. All you need to do is insert a can of mechanical oil and let VBG MechMatic handle the maintenance of your coupling. A light on the control unit will indicate when the can is empty.

- VBG Driver Assist – jackknife warning and coupling assistance in one. With sensors on either side of the drawbeam and reflectors mounted on the drawbar, VBG Driver Assist helps you couple in the most challenging environments, and it also warns you about difficult jackknifing situations. Through a speaker in the cabin, you get instructions on how to manoeuvre to ensure that coupling is done without hassle, and, like a reverse signal, the system emits signals that gradually increase in frequency when there is a risk of jackknifing.

If you still have some questions about our products, you are always welcome to contact us for assistance!

Recommended reading

How Do You Build the Optimal VBG System?

How can new technology streamline and improve the workday for hauliers?