How Do You Build the Optimal VBG System?

Coupling equipment is the link between the truck and trailer and must always have maximum performance and safety. This places high demands on the constituent products in a coupling system to ensure safe transport on our roads. But what do we mean by coupling equipment, and what are the constituent parts? An array of components is required for the coupling between the truck and trailer to be strong and safe on the roads. To show you how to easily choose the right coupling equipment, we have created this step-by-step guide.

1. Calculate the performance values

Start by calculating the truck combination’s weight, length, and axle load, and take into account the type of goods it will transport. These values are then entered into the VBG Performance Value Calculator (PVC) to find out the requirements for the specified coupling equipment.

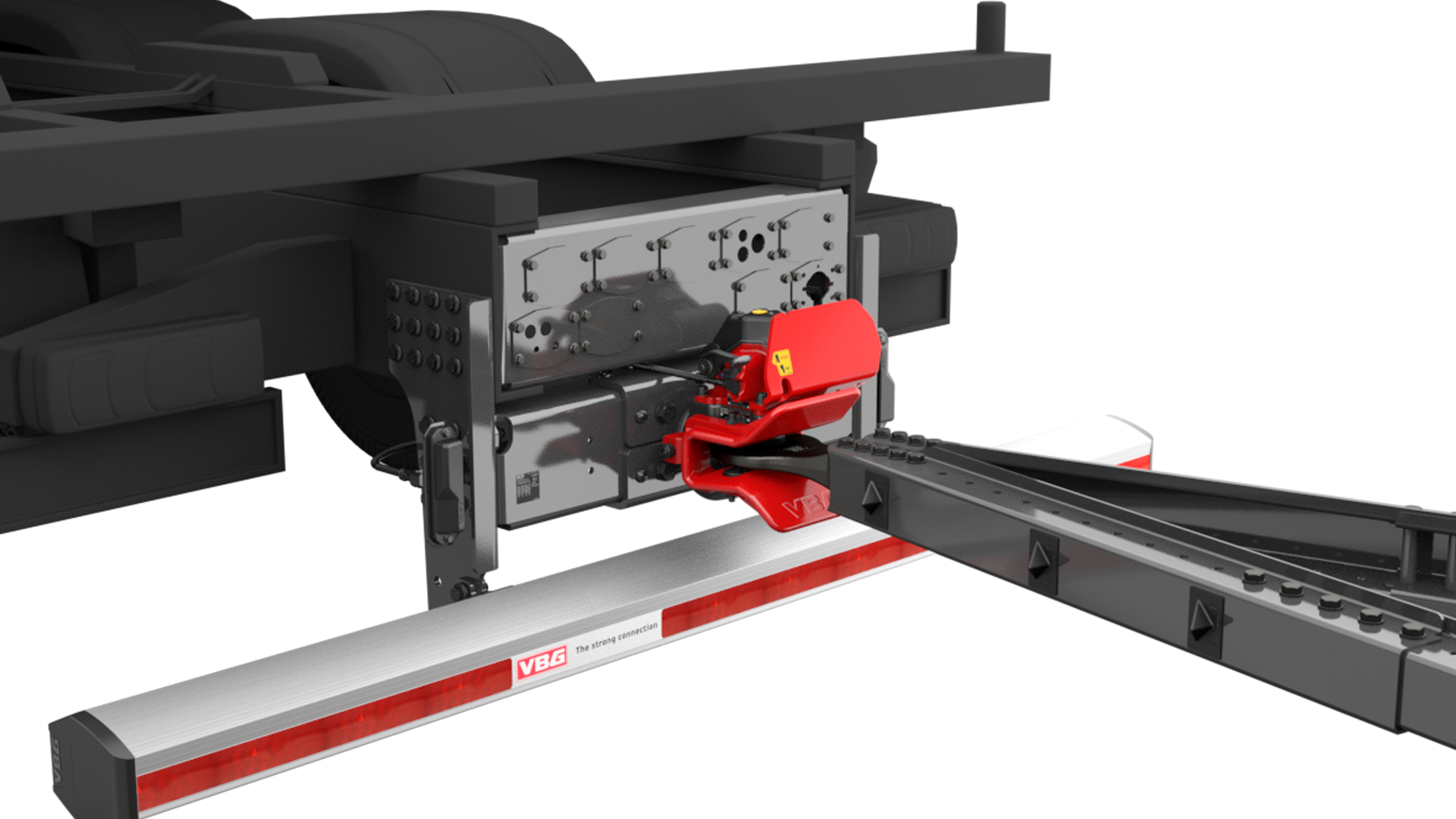

2. Select the drawbeam system

Once the performance values have been determined, it is time to select the drawbeam system, which is the link between the coupling and the truck chassis. Underslung installation is the most common, where the drawbeam is mounted under the chassis using an endplate kit. The endplates determine the height of the coupling, based on the G measurement – the distance from the bottom hole row on the chassis to the position of the coupling bolt.

3. Choose the right coupling

Do you want a manually operated or air-assisted coupling? What coupling mouth length do you need? On our website you will find all our coupling models as well as information about which uses are best suited for each model.

Air-assisted couplings require both a valve box and an indicating kit to show the coupling status in the driver’s cab.

4. Underrun protection

UNECE R58 Rev. 3 regulations place high demands on underrun protection. Among other things, the requirements stipulate that underrun protection must be able to withstand higher impact forces than in the past.

5. Simpler coupling equipment maintenance with smart accessories

VBG MechMatic: Blows clean and lubricates the coupling automatically.

VBG Driver Assist: Assists during coupling and warns about jackknifing via sensors and audible signals.

Are you wondering how to build your next optimal VBG system for maximum performance and safety?

Contact us and we’ll find a world-class solution for you!

Recommended reading

How can new technology streamline and improve the workday for hauliers?

How Do I Build a VBG System?