How can new technology streamline and improve the workday for hauliers?

Haulier Peter Greisen has a 3-axle Volvo FH750 with a 4-axle trailer for transporting feed. The truck has been running with the VBG Driver Assist system for almost a year and a half, and Peter Greisen is very pleased. VBG Driver Assist gives him a better and more relaxed work environment, while also acting as insurance against expensive damage.

Peter Greisen is a haulier with almost 40 years of experience in the transport industry, 12 of which he spent as a truck driver, before becoming a haulier in 1998. He runs a haulage company that, at one time, had five trucks, but which today has a single truck. Peter shares it with a driver so they can keep it running six days a week

“I have been involved in the transport of feed for almost 25 years, and it’s still my focus today,” says Peter, who is based in Aabenraa in Southern Jutland, but who drives all over Denmark for DLG.

He received his current Volvo FH750 new at the beginning of 2023, and just before delivery, he became the first customer in Denmark to have VBG Driver Assist installed on the vehicle combination. In fact, he ordered it more than a year earlier after seeing it demonstrated at VBG’s stand at the Herning Transport Fair, and fortunately it was ready and installed before the delivery of the new truck.

“I’ve always been very concerned about safety,” says Peter. “On my previous vehicles, I had mounted a camera next to the coupling, which I could use when reversing the truck and when coupling the trailer. It worked more or less, but VBG Driver Assist works much better.”

Peter finds the system especially beneficial when he drives his truck combination to the farmers, where he needs to navigate narrow farm areas and between nearby buildings. For example, it works optimally when he has reversed his trailer into a narrow gap and decoupled it to drive in and load the tractor. When the time comes to couple the truck combination again, but reversing from the other side to be able to drive forwards, he can precisely align the coupling with the drawbar eye on the first attempt.

“I drive both when it is light and when it is dark, and in all kinds of weather,” explains Peter. “VBG Driver Assist is utterly superior to cameras that do not always work optimally in all conditions. VBG’s radar sensors and reflectors are not affected by whether it is light or dark, and work perfectly in all kinds of weather.”

It provides a more relaxed working environment when Peter does not need to worry about coupling incorrectly. Damage to the coupling and drawbar adds up quickly, but downtime for repairs can cost even more.

“It’s difficult to place an exact amount on the financial savings, but every time the system prevents damage, it pays for itself,” says Peter. “And even though I have not exactly been plagued by expensive damage in the past, I have experienced that both I and my drivers have ‘missed the mark’.

“The peace of mind that comes with having a reliable system cannot be assigned a price, but like insurance, it is only when the damage occurs that the insurance shows its worth. However, I’m convinced that it’s definitely on the plus side.”

A system for both hauliers and drivers

JACKKNIFING WARNING

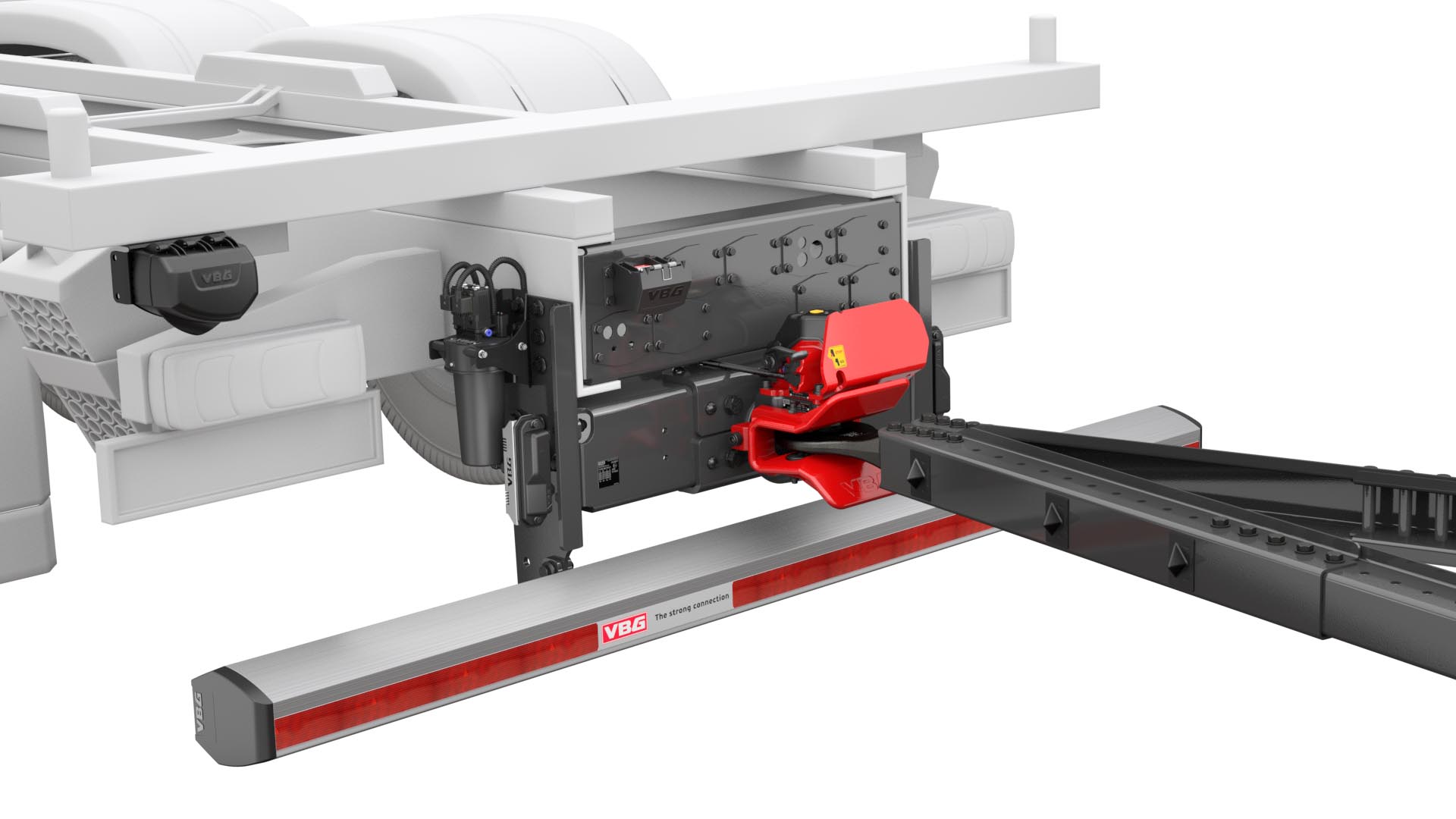

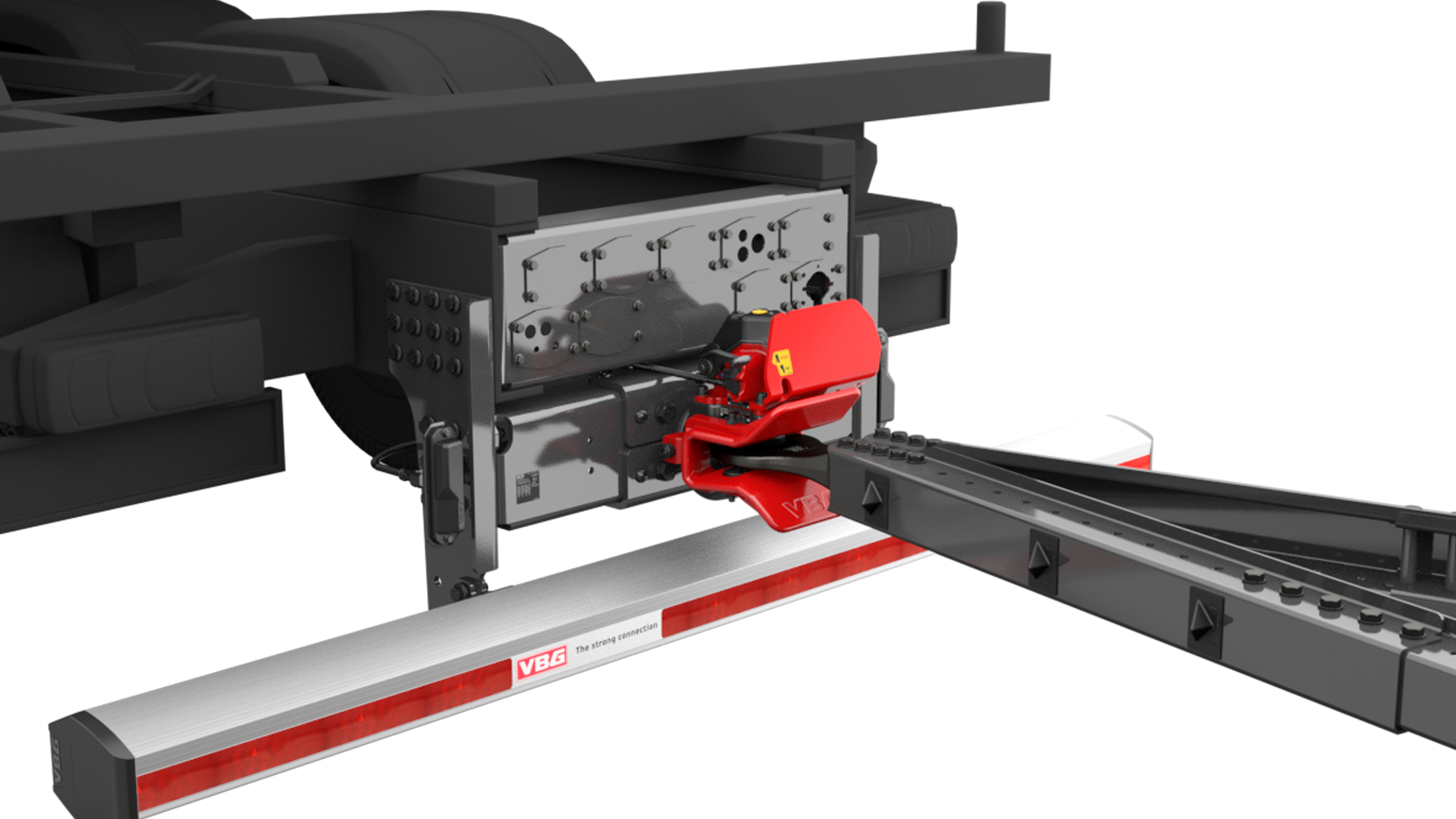

The system is designed to warn against jackknifing between the coupling and the drawbar and to guide during coupling. It can be used on tractor-trailer vehicle combinations.

The system comprises several radar sensors that are placed around the tractor coupling, as well as several reflectors mounted on the trailer drawbar. When the distance/angle between the coupling and the drawbar approaches a critical level, the driver is alerted by audible signals in the cab.

The audible signals begin at an angle of 40 degrees and end with a constant warning sound when the maximum angular range is reached. This angle is individually adjusted when installing the system and can vary depending on the location of the coupling, rear overhang, etc. The jackknife warning is only active when reversing.

COUPLING GUIDANCE

The system’s radar sensors detect the position of the drawbar and guide the driver to quick and safe coupling. The driver does not have to leave the truck’s cab, and can focus on precisely aligning the coupling with the drawbar eye at the end of the drawbar.

Would you like to know more about how VBG Driver Assist can help you, as a haulier, save costs and maximise uptime?

Recommended reading

How Do You Build the Optimal VBG System?

How Do I Build a VBG System?