How Can Jackknife Damage Costs Be Reduced?

Damage caused by jackknifing can be very costly in terms of repairs and time losses. Can these costs be reduced in some way? We think they can. By introducing a warning system for the driver in the truck cab, many incidents can be avoided.

What is jackknifing?

We have previously communicated that VBG has been developing a driver-assist system that, among other things, will warn the driver before jackknifing occurs. The idea is that the system will serve as a support tool and help the driver to focus on the right things. The development work is now complete, and we will soon be able to launch the system and offer it as an option for VBG’s coupling system.

When a truck and trailer jackknife, not only is it serious from a safety standpoint, but it also results in significant costs.

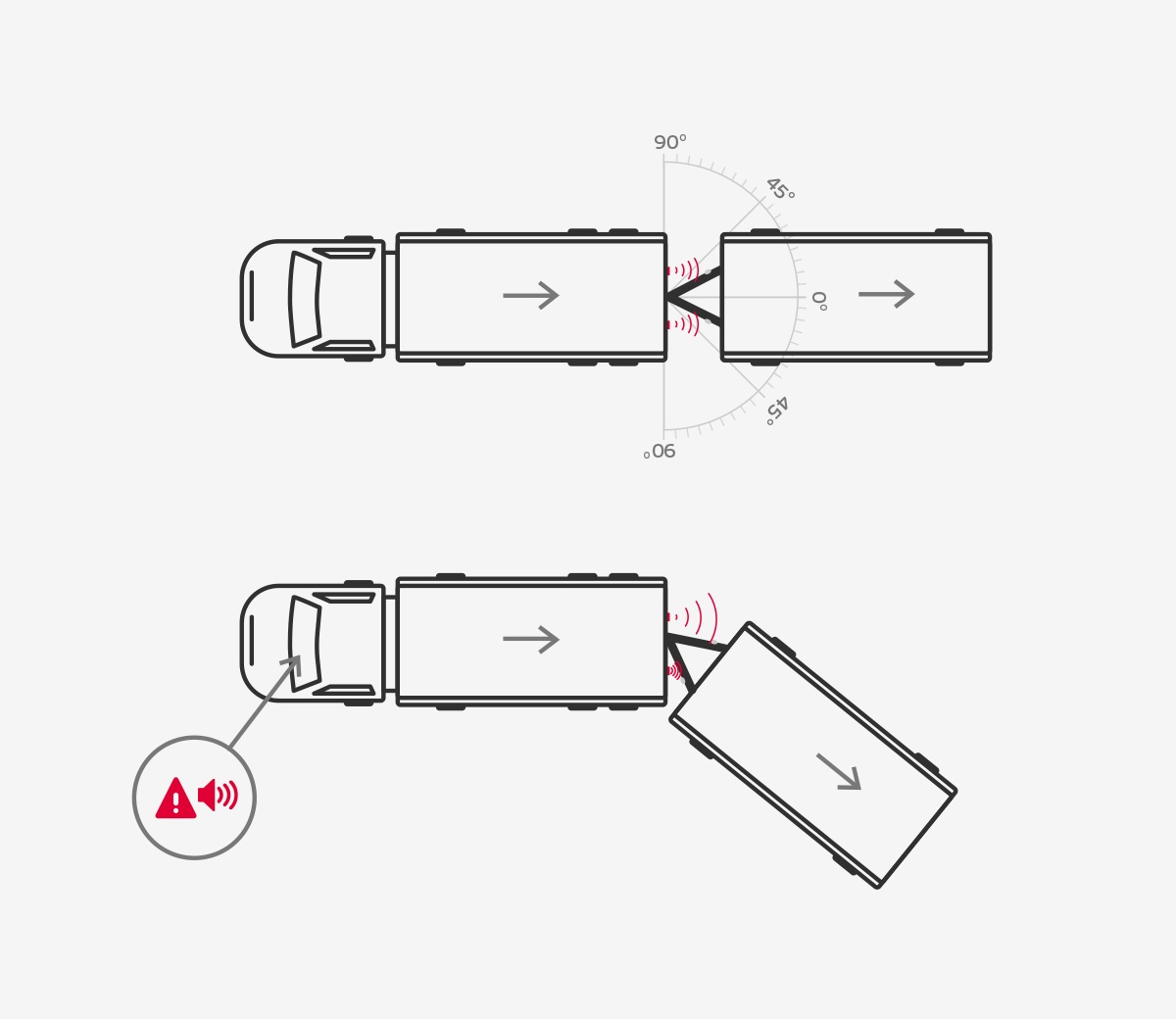

Jackknifing can occur at roadworks, construction sites and in forests when a timber truck reverses on a narrow path and the drawbar folds too close to the truck, causing it to come into contact with other components mounted on the chassis. This quickly leads to mechanical damage.

What are the costs of jackknife damage?

The costs can vary but can easily become very high. And if this type of damage recurs, profitability can decrease in various ways.

- Repair costs: SEK 13,000-50,000

- Truck downtime

- Delayed customer deliveries

- Job losses

- Logistics planning

- Staff planning

If the endplates, drawbeam, coupling, drawbar eye and drawbar are damaged, for example, repairs may cost between SEK 13,000 and SEK 50,000 – each. And this is just the cost of repairs following a damage inspection.

Remember! Damaged caused by jackknifing requires the coupling’s horizontal bolt to always be inspected according to the applicable guidelines “Guidelines for Inspection, Servicing and Maintenance”.

VBG Driver Assist – innovation for safety

Safety is always the highest priority for VBG, and, in this case, it is combined with an innovative solution to a recurrent problem in the transport industry. VBG conducted a customer survey and found that jackknifing is a problem for which most customers would like a solution.

The development project for a jackknife warning system and coupling guidance – VBG Driver Assist – is almost complete. The system warns the driver in good time when there is a risk of jackknifing so that the driver is able to rectify the situation and regain control. This not only increases the safety of the driver and other road users, but also prevents expensive damage to the vehicle rig as described above.

New technology that provides a new level of safety

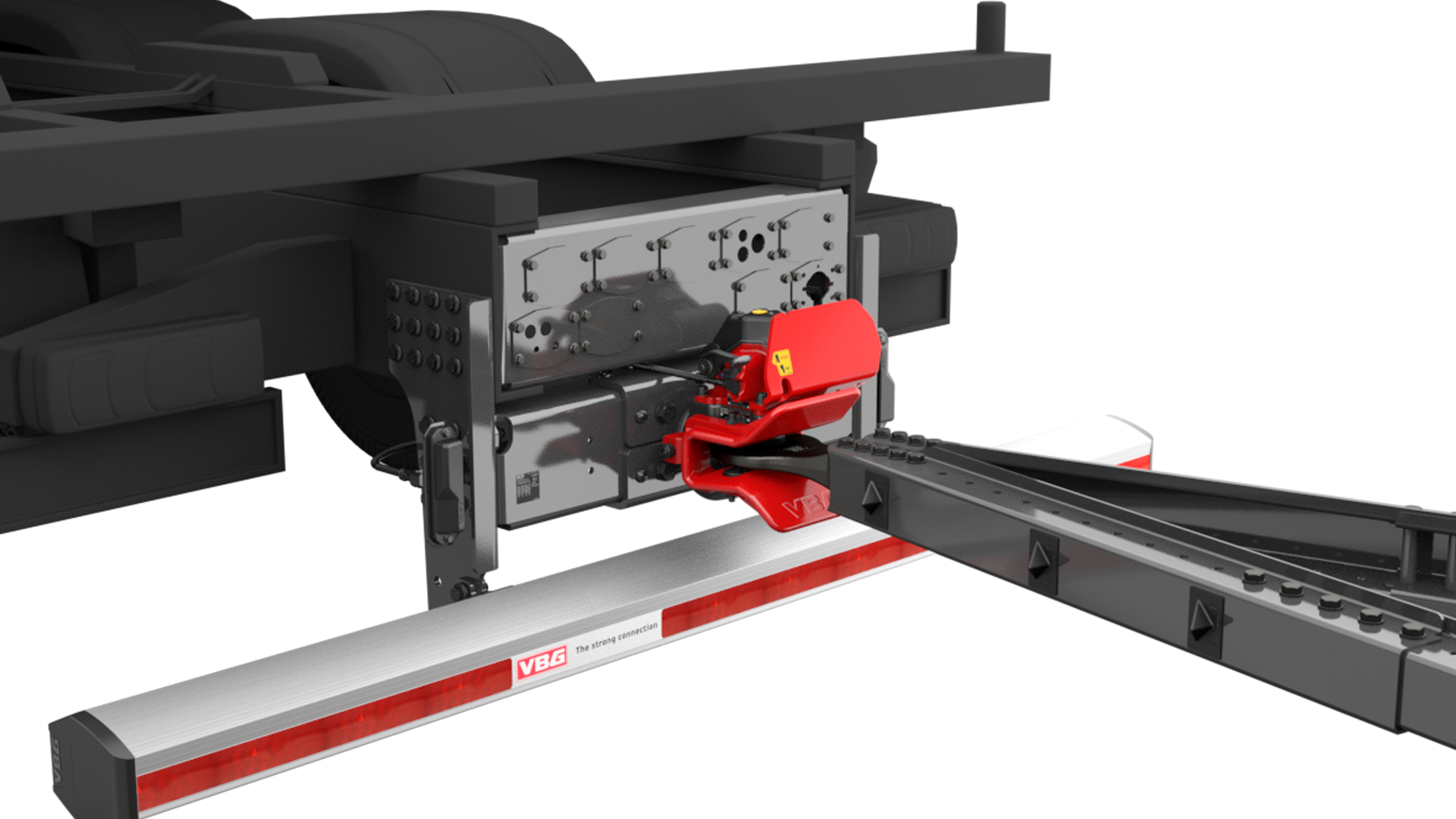

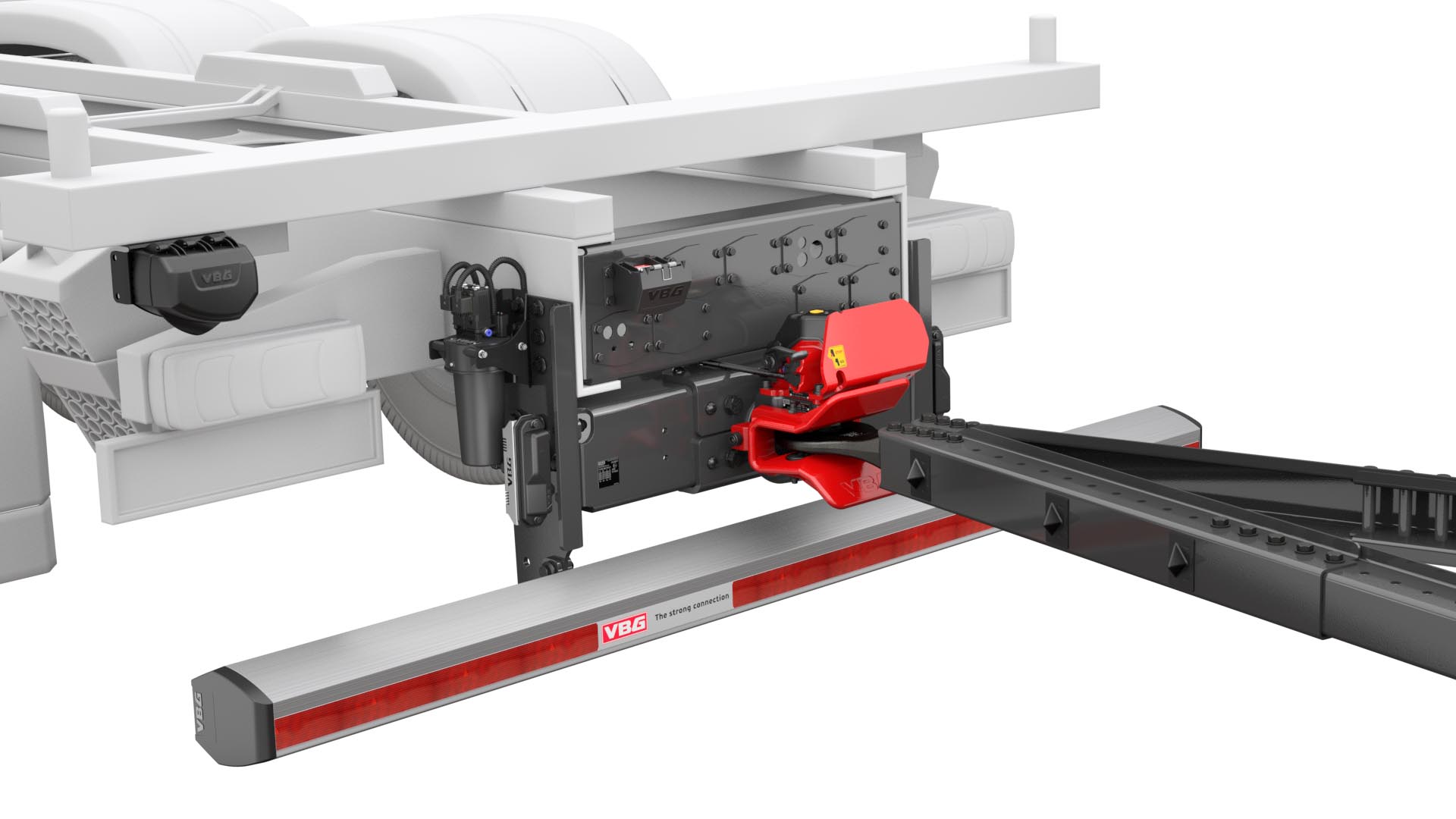

The new system is based on radar technology, which produces a robust and reliable solution. Radar sensors on both sides of the coupling in combination with reflectors on the drawbar enable highly precise angle measurement. It can also be used for guiding when coupling a trailer.

A clearly audible jackknifing warning is sounded in the driver cab. It works similarly to a vehicle reverse warning system, the more frequent the beeps, the closer the jackknifing angle. The warning angle is set during initial calibration when installing the system.

Remember that VBG’s “Guidelines for Inspection, Servicing and Maintenance” must always be followed for an accurate assessment. It describes how damage inspection and assessment must be conducted, as well as the correct way to carry out servicing and maintenance to ensure the longest possible service life of the products.

Would you like to know more about our new system?

Recommended reading

How Do You Build the Optimal VBG System?

How can new technology streamline and improve the workday for hauliers?