Avoid unnecessary jackknifing damages

Most of us want to find ways to save time and money. By decreasing costs for jackknifing damages, you meet these targets. But how shall you do? Well for example by using a warning system for the driver in the cabin.

What is Jackknifing?

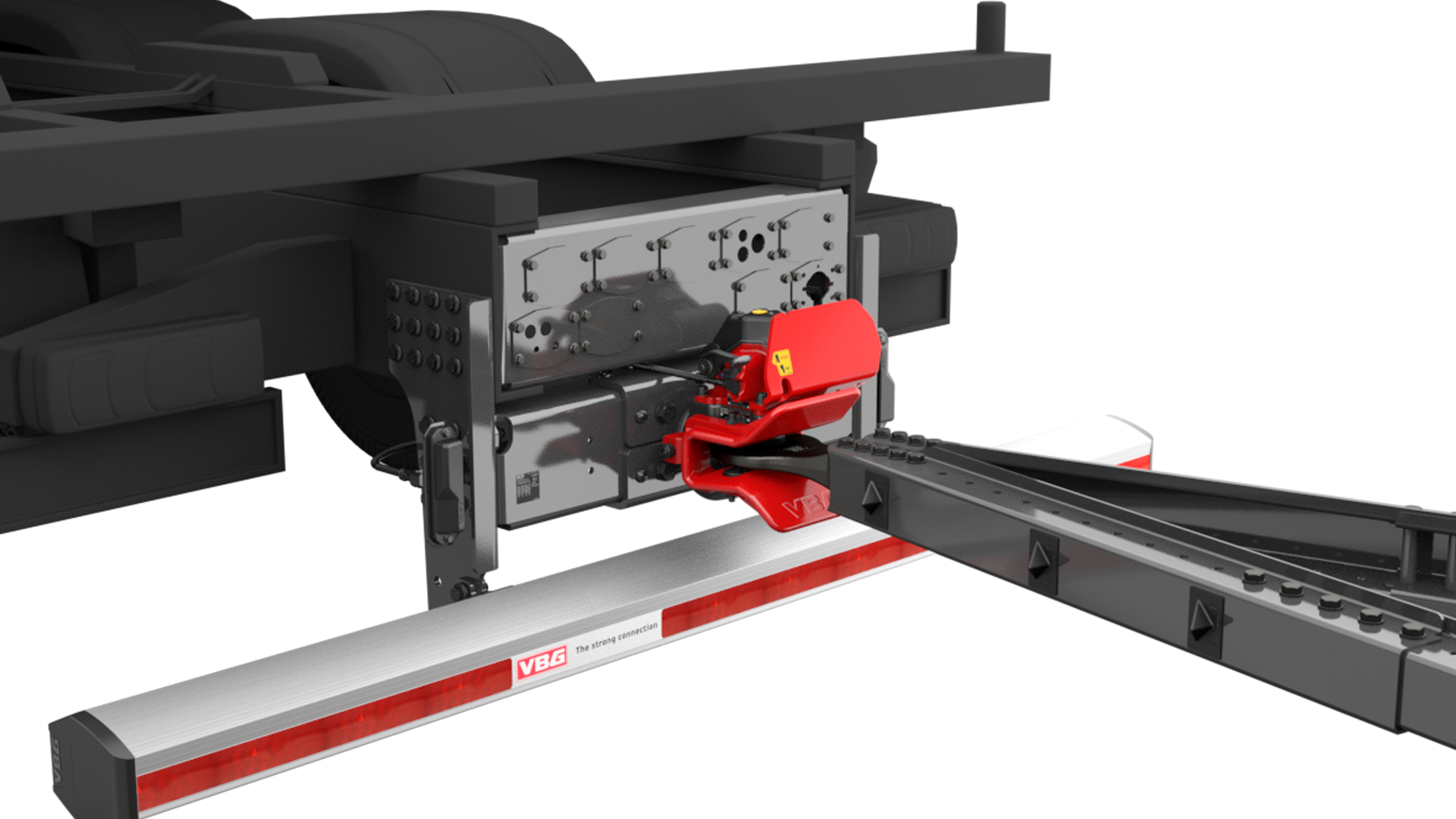

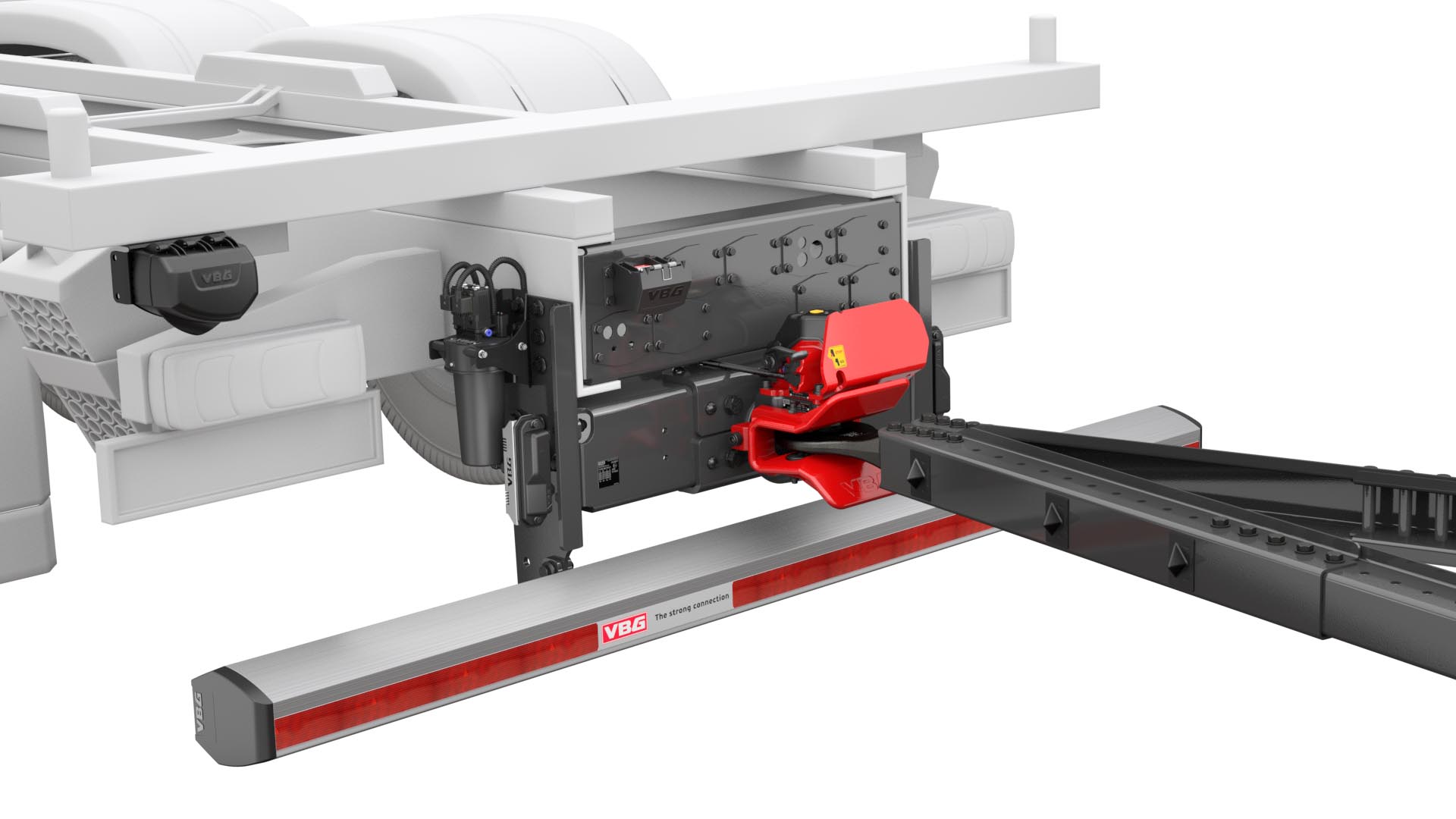

Regularly reviewing your operating expenses is both natural and necessary. If you have issues with costs related to jackknifing damages, you can of course solve the problem in several ways. For example, by drivers training and by putting a good camera solution at the back of the truck. But now there is also another alternative available, VBG Driver Assist. It’s VBG:s own developed driver assistance system that warns the driver before a jackknifing situation occur. The idea with the system is to support so that the driver can focus on other important things, basically a supportive system for the daily work. The system is a add on to VBG:s couplings Generation 3.

When a truck and trailer jackknife, not only is it serious from a safety standpoint, but it also results in significant costs.

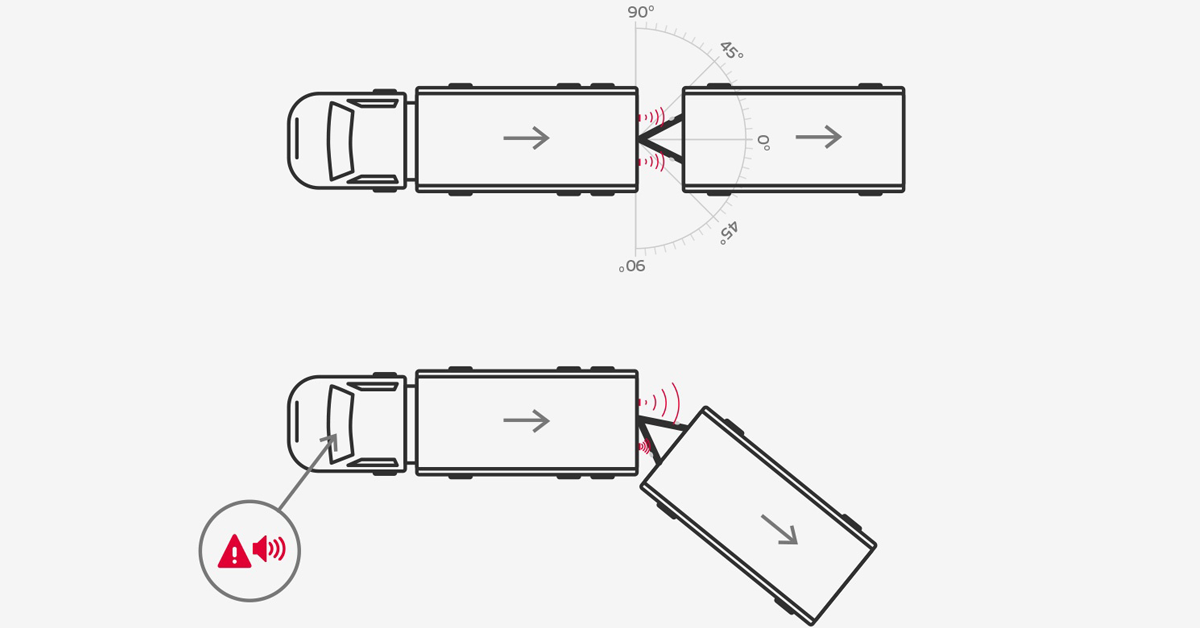

Jackknifing can occur at roadworks, construction sites and in forests when a timber truck reverses on a narrow path and the drawbar folds too close to the truck, causing it to come into contact with other components mounted on the chassis. This quickly leads to mechanical damage.

What costs are you avoiding with VBG Driver Assist?

The costs can vary but can easily become very high. And if this type of damage recurs, profitability can decrease in a dramatic way.

Costs of jackknife damage

- Repair costs, 1300 – 5000 €

- Truck downtime

- Delayed customer deliveries

- Job losses

- Logistics planning

- Staff planning

If the endplates, drawbeam, coupling, drawbar eye and drawbar are damaged, for example, repairs may cost between 1300 and 5000 € – each. And this is just the cost of repairs following a damage inspection.

Remember!

Damage caused by jackknifing requires the coupling’s horizontal bolt to always be inspected according to the applicable guidelines “Guidelines for Inspection, Servicing and Maintenance”.

VBG Driver assist – innovation for safety

Safety is always the highest priority for VBG, and, in this case, it is combined with an innovative solution to a recurrent problem in the transport industry.

The development project for a jackknife warning system and coupling guidance – VBG Driver Assist – is completed and was displayed for customers at the Elmia Lastbil fair in Jönköping in August.

The system warns the driver in good time when there is a risk of jackknifing so that the driver is able to rectify the situation and regain control. This not only increases the safety of the driver and other road users, but also prevents expensive damage to the vehicle rig as described above.

New technology that provides a new level of safety

The new system is based on radar technology, which produces a robust and reliable solution. Radar sensors on both sides of the coupling in combination with reflectors on the drawbar enable highly precise angle measurement. It can also be used for guiding when coupling a trailer.

A clearly audible jackknifing warning is sounded in the driver cab. It works similarly to a vehicle reverse warning system, the more frequent the beeps, the closer the jackknifing angle. The warning angle is set during initial calibration when installing the system.

Remember that VBG’s “Guidelines for Inspection, Servicing and Maintenance” must always be followed for an accurate assessment. It describes how damage inspection and assessment must be conducted, as well as the correct way to carry out servicing and maintenance to ensure the longest possible service life of the products.

Would you like to know more about our new system?

Recommended reading

How Do You Build the Optimal VBG System?

How can new technology streamline and improve the workday for hauliers?