Service Your Trailer Coupling: Step-by-Step Guide

To ensure your coupling equipment lasts a long time and remains safe for driving, there are simple guidelines to follow. Contribute to increased safety on our roads and reduce the need for repairs by following VBG’s guidelines.

Guidelines are there to be followed

Trucks that stand still cost money. The haulier loses money and customers have to wait for their goods - and this leads to stress for the driver. But there are a few simple tricks to help you avoid unexpected repairs and unwanted downtime. And that means keeping your fleet’s coupling equipment in good condition.

You may be wondering how - and whether there’s something special you need to do?

No, it’s as simple as following our service and inspection guidelines. If you make it a habit, it will have clear and positive effects on both the safety and sustainability of your company. You won’t have to worry about the unexpected, and you will free up time to grow your business for the future.

The guidelines help keep your system safe and reliable

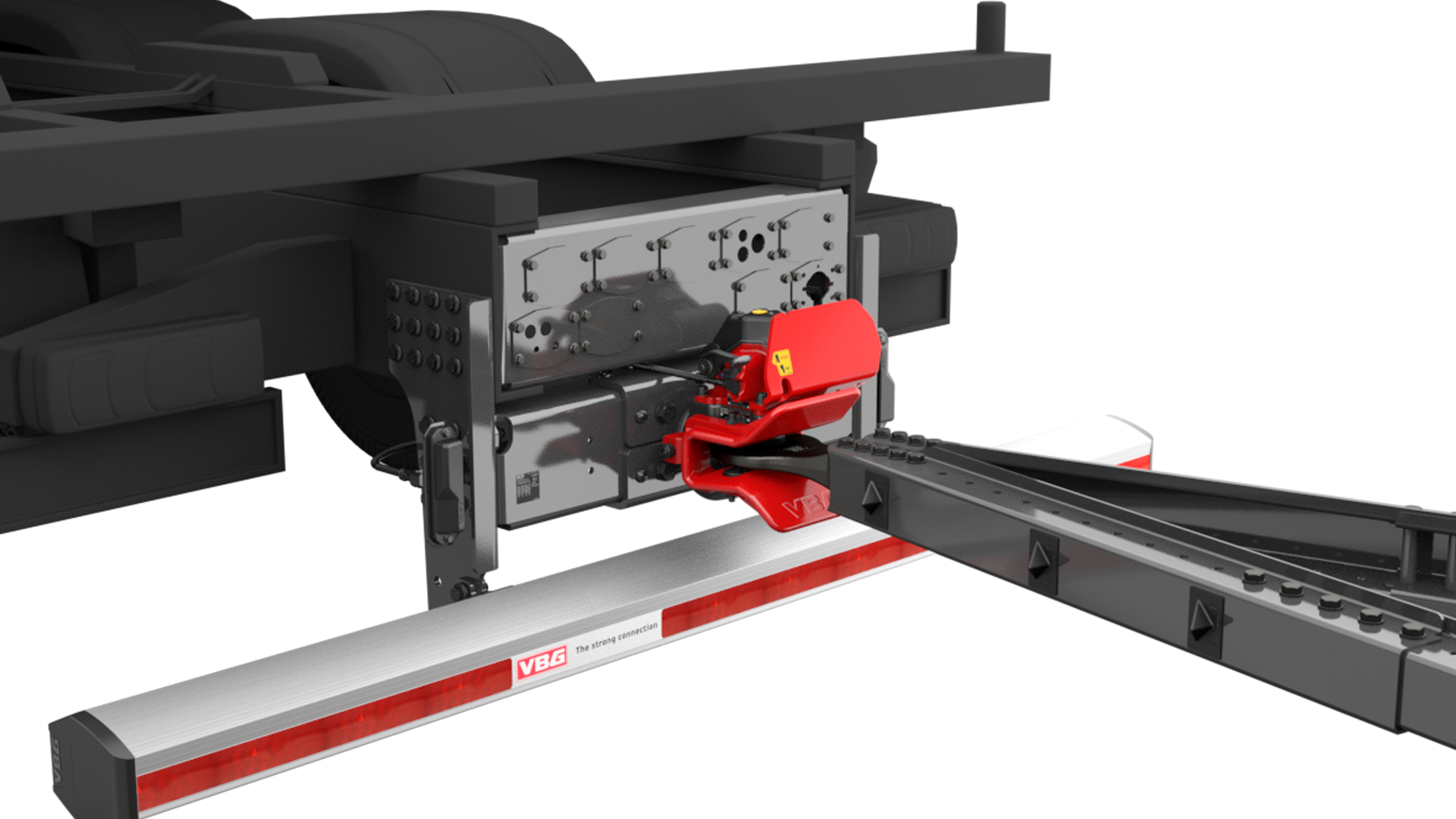

The wear on the coupling parts between the truck and trailer must withstand very high forces. These are parts that, in normal use without incidents, wear over time. But if you have routines to regularly service and maintain them, they will last longer and remain safe to use on the roads.

Step-by-step - Coupling function check

Always start by inspecting the functionality of the coupling.

1.Open the coupling and ensure it is unhooked.

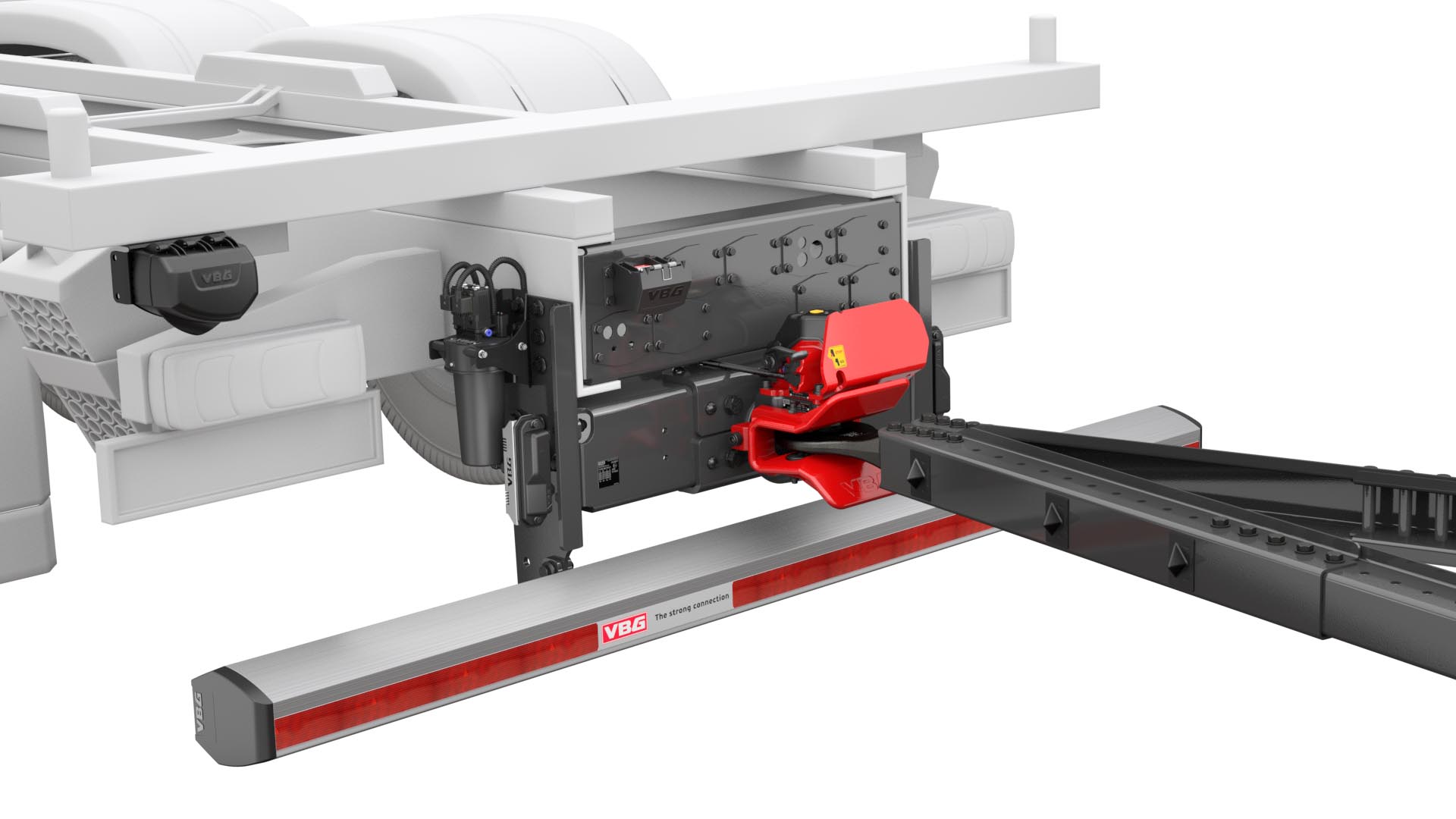

On manual couplings, this is done with the handle, whereas the valve box must be used on assisted couplings. For an assisted coupling (AM/PA), check that the indicator light in the cabin is red, which means the coupling is open.

Using a crowbar, lift the bolt so that it moves down into the locked position. Check that the indicator pin shows the coupling is closed. For an assisted coupling, check that the indicator light in the cabin is green, which means the coupling is closed.

2. If you have an assisted coupling, listen for any air leaks.

3. Measure wear

- Coupling bolt wear is easily measured with gauge or calliper. It is also important to check the vertical play.

- Wear on the upper and lower jaw bushings must also be checked with a gauge or calliper.

- The wear indicator on each wear plate must be inspected to ensure your coupling remains within the correct limits for safe driving.

NOTE! The complete inspection, service, and maintenance guidelines contain additional steps that should be followed to ensure safe driving and operation.

Service your coupling for safe driving

-

Create a schedule for the service

The length of the service interval depends on the type of trailer and loads, road and climate conditions, etc. The service can be carried out in conjunction with other vehicle inspections, such as every 60,000 or 90,000 km.

-

Check wear limits

If any of the wear limits have been exceeded, or if the product’s function has been impaired, repairs must be carried out immediately.

-

Cleaning routines

Clean and lubricate the coupling every week. -

Are parts visible that need to be visible?

Check that all type plates and warning and information labels are where they should be and that they can be clearly read. If they are so worn that they are hard to read or have fallen off - order new ones. -

Is there damage?

If there is damage caused by jackknifing, off-road driving, or reversing, for example, the vehicle must not be driven until the coupling is replaced.

-

For everyone’s safety, switch everything off

Before starting the servicing, check that all coupling equipment is depressurised and the power is off. Disconnect the air supply and power to actuator-assisted couplings.

As mentioned, these are just a few examples. The most important thing is that we all help each other and take responsibility for drive our transports safely and securely on the road. Prioritise and plan for regular servicing and inspection for everyone’s safety.

Read more about the VBG servicing and inspection guidelines on our website for a full description.

Recommended reading

How Do You Build the Optimal VBG System?

How can new technology streamline and improve the workday for hauliers?