Jackknifing Damage and Repairs – what’s involved?

Jackknife damage can result from several different transport situations and repairs can understandably be expensive. Is there a way to prevent damage?

When a truck and trailer jackknife, not only is it serious from a safety standpoint – no one wants to encounter a trailer that has separated from the towing vehicle – it also results in significant costs.

Jackknife damage can occur at roadworks, construction sites and in forests when a timber truck reverses on a narrow path and the drawbar folds too close to the truck, causing it to come into contact with other components mounted on the chassis. This quickly leads to mechanical damage.

The costs vary, but one thing is sure: they will probably be high. If the endplates, drawbeam, coupling, drawbar eye and drawbar are damaged, for example, it may cost anywhere between SEK 13,000 and 50,000 to repair. And this is just the cost of repairs following a damage inspection.

For the jackknife damage the coupling’s horizontal bolt must always be inspected according to the applicable guidelines “Guidelines for Inspection, Servicing and Maintenance”.

On top of this, the truck’s downtime must be taken into account, which begets more problems such as job losses, delayed customer deliveries, logistics planning, staff issues, etc.

VBG conducted a customer survey and found that jackknifing is a problem for which most customers would like a solution.

Jackknife warning – innovation for the sake of safety

Safety is always the highest priority for VBG, and, in this case, it is combined with an innovative solution to a recurrent problem in the transport industry.

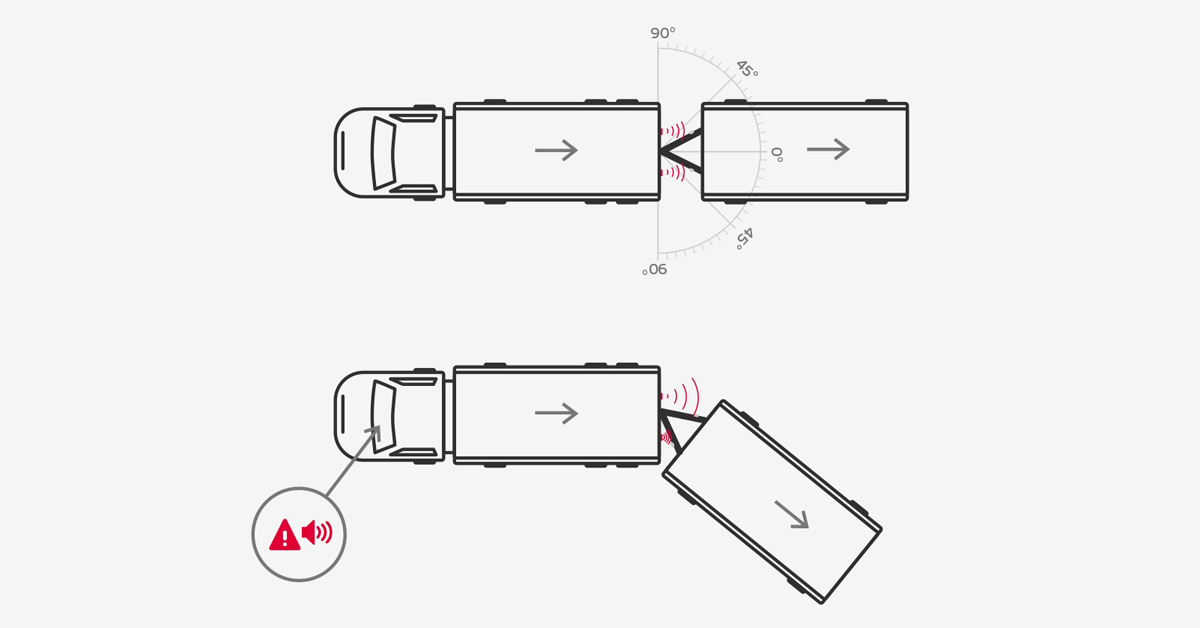

One of our development projects is focusing on a jackknife warning system. The system warns the driver in good time when there is a risk of jackknifing so that the driver is able to rectify the situation and regain control. This not only increases the safety of the driver and other road users, but also prevents expensive damage to the vehicle rig as described above.

Also read: “New Jackknife Warning System”

Remember that VBG’s “Guidelines for Inspection, Servicing and Maintenance” must always be followed for an accurate assessment. It describes how damage inspection and assessment must be conducted, as well as the correct way to carry out servicing and maintenance to ensure the longest possible service life of the products.

Recommended reading

The year in review on The Strong Connection – 3 articles setting the tone for 2026

Efficiency, Safety, and Sustainable Transport – Top 5 Articles and Insights of 2024