Critical road safety legal requirements for underrun protection

In the event of a collision, the underrun protection prevents smaller vehicles from becoming lodged underneath the truck or trailer. But how do you know which underrun protection is best for your truck combination? What laws and regulations exist concerning underrun protection?

Development of Underrun Protection

In the Nordic countries, legal requirements for rear underrun protection for trucks were gradually introduced starting in the 1990s, and Sweden was the first to do so in 1993.

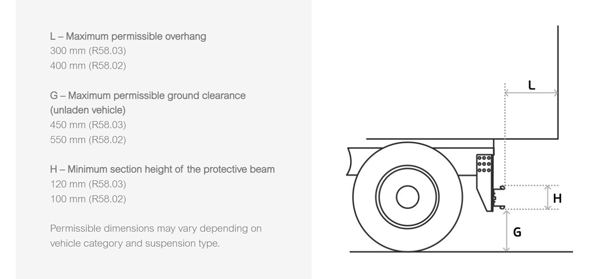

The development of this critical safety solution for trucks is encompassed by strict legal requirements, which are currently regulated by UNECE. The regulations concerning underrun protection are currently governed by Regulation UNECE R58 revision 3 (R58.03), which came into force on 1 September 2019. The regulation has a direct effect on components, which must be designed and tested to withstand the greater stresses stipulated in the new regulation. R58.03 applies to all new type-approved vehicles. This increases the safety of both the driver and other road users.

The protective beam, which is part of the underrun protection system, is also sometimes referred to as the Mansfield bar. This name stems from the tragic accident in which beloved actor Jayne Mansfield was killed in 1967 when her car collided with a truck. The accident indicated the need to design and implement effective underrun protection.

Fixed, hinged or sliding – which underrun protection should I install on my truck?

There are different types of underrun protection to ensure that you have a system that suits you and your needs. First of all, select the type of underrun protection you require. Is a permanently installed system sufficient, or do you require one that can be removed? Depending on how your coupling is mounted, you may need hinged underrun protection. Or, if you have a tipper truck for contracting, a sliding system may be the optimal solution for you. Do you want a fully prefabricated system, or perhaps you need to assemble your own customised system?

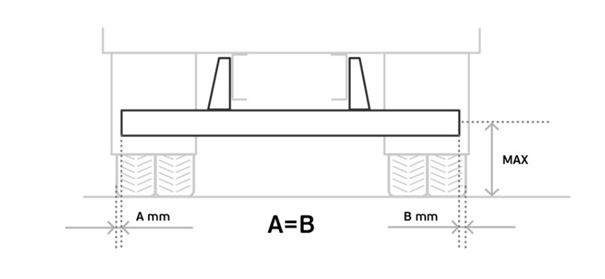

The type of underrun protection determines which components you can choose from. Selection is partly influenced by how and where you want the system mounted on the vehicle, and partly by statutory safety distances and dimensions.

Fixed underrun protection

Fixed underrun protection is permanently in place and provides the greatest possible safety if an accident should occur. You can also choose underrun protection that can be completely removed if necessary. A fixed system consists of endplates that can be easily bolted to the vehicle chassis. The protective beam is mounted to these with a customised bracket. With an extended attachment/arm, you can move the position of the protective beam backwards. You can also select removable underrun protection, which can be lifted off if necessary.

Hinged underrun protection

If the coupling is mounted far underneath the vehicle, the underrun protection may obstruct coupling to the trailer. A hinged system can be easily folded away to facilitate coupling. To install hinged underrun protection, endplates are required with articulated attachment/arm to which the protective beam is secured with a customised bracket. The endplate is bolted to the vehicle chassis.

Sliding underride protection

Sliding underrun protection enables you to slide in the protective beam for increased space. This is ideal on tipper trucks, for example. The system consists of endplates (which are bolted to the chassis) with articulated attachment/arm to which the protective beam is secured with a customised bracket.

Underrun protection FAQs

CAN I HAVE OUTLINE MARKING ON A PROTECTIVE BEAM?

Yes, it is approved as part of the outline marking. Most of VBG’s protective beams are available with outline markings. For detailed information, refer to Instructions for Outline Marking.

The latest regulatory framework is available in accordance with UN/ECE-48 (part of the framework directive), which regulates reflectors and outline marking.

CAN I MOUNT A BALL COUPLING TO THE UNDERRUN PROTECTION?

Refer to the relevant mounting instructions to check what applies.

WHEN IS THE VEHICLE FRAME STRONG ENOUGH TO ATTACH THE UNDERRUN PROTECTION?

All VBG underrun protection is certified according to the new directive ECE R 58.03. The products are distinguished by the suffix 100 or 180 in the product name, where 180 corresponds to vehicle weights of 21 tonnes or more, and 100 corresponds to vehicle weights of up to 12 tonnes.

In order for the certificate to be valid for the installation, requirements are imposed on the strength of the vehicle frame. Do you want to read more about how calculations for beam bending are performed?

I’VE HAD A SERIOUS REAR-END COLLISION AND THE PROTECTIVE BEAM IS DEFORMED. CAN I SIMPLY REPLACE THE PROTECTIVE BEAM ON MY UNDERRUN PROTECTION?

Yes, you should do this to comply with the legal requirements. Protective beams are available as spare parts for our systems.

Would you like to know more about what the new Regulations R58.03 entails?

Recommended reading

The year in review on The Strong Connection – 3 articles setting the tone for 2026

The transition enters its next phase – Future outlook 2026